Yes. There is the potential for hydraulic

fracturing to seriously contaminate aquifers and damage the environment, but

only if regulations are not followed, and only to the same extent as many other

modern industrial processes.

There are two issues here:

- How might fracking, its wastes or product contaminate or damage the surface and sub-surface environment.

- Is it acceptable for us to risk exposing the British countryside to possible industrial contamination.

The second issue is a moral one that has no clearly correct response. It includes concepts such as the balance between human development and the wider environment, the acceptability (or not) of exploiting natural resources for human greed when each of us turn to an hydrocarbon-using product every 2 minutes, and the pervasive need to not have it happen in my back yard.

Let us assume, therefore, that you as a reader of this blog, are capable of making your own mind up on the second point, and let’s see to what extent that hydraulic fracturing might contaminate aquifers (the layer of rock containing the water that is extracted for domestic and other purposes).

Contamination sources

If an aquifer of potable water is to be contaminated or the environment damaged, there must be a source of contamination. Some sources are clear, while others are not. Possible sources, though not exhaustive, are as follows:

- Gas from the shale gas formation

- Gas from other formations not targetted by the shale gas production

- Natural shallow biogenic gases disturbed by drilling

- Drilling fluid

- Fracking fluid

- Flow-back fluid

- Lack of water if water is extracted from the local environment

- Industrial waste associated with the presence of drilling plant

- Personal waste and litter associated with the drillers and protestors

- Building waste associated with site development and remediation

“The air and surface water samples generally show ambient conditions indicative of good environmental quality. Groundwater results have displayed some elevated heavy metals and sodium and has been confirmed to contain elevated dissolved methane and ethane gas.”.

The content of drilling and fracking fluids will be discussed in a separate posting, while the flow-back fluid can have raised levels of naturally occurring radioactive materials (NORMs), and should also be considered as a potential harmful substance as a precaution.

Lack of water can also pose a threat to the environment, and is included here to represent the case where water is extracted from local surface waters, and may pose a danger to local wetlands and ponds. However, it is extremely unlikely that the use of surface waters would ever be allowed in the UK unless the source was extremely robust (e.g., a nearby reservoir). By contrast, it is a big problem in Texas, where their three main aquifers have been under severe threat for many years from human consumption, irrigation and golf courses. Here indiscriminate use of aquifer water for fracking has exacerbated an already difficult situation, with whole towns running out of water

The last three sources of possible pollution, represent a small but not insignificant group of environmental threats, and include mislaid metalwork, dropped hammers, Mars bar wrappers (from those who have been experimenting on earthquakes!), sanitary provision for workers, and even badly disposed building sand and gravel. Existing strict planning and site regeneration rules should minimise their effect, but often monitoring and enforcement are not carried out due to cut-backs.

Balcombe has recently discovered that environmental protestors represent as much of a source of these threats as an exploration rig, with particular concern about the indiscriminate disposal of excrement and urine, according to one resident “…most locals had been disgusted by the behaviour of protestors urinating and defecating in gardens.”.

Could the contamination be serious?

Yes. In all cases the contamination source is or contains chemicals which are alien to the damaged environment. One might describe the gas as natural, but not so in an aquifer that did not previously contain it. Naturally occurring radioactive materials are clearly natural, but not so in ponds! And so on.

The goal is to reduce the addition of these items to a level where it is insignificant, or if that is impossible, then to a level which is acceptable considering the general benefits that the exploitation provides.

Why is the type of gas important?

“It is a little known fact that many aquifers naturally contain methane. So its presence in tap water is not proof of contamination.” - Mike Stephenson, Head of Energy Science at the British Geological Survey

Gas, which occurs naturally in the subsurface from the degradation of organic material, has two sources, which can be identified using geochemical techniques:

- Biogenic - formed at shallow levels from the action of soil microbes on organic remains, and

- Thermogenic - formed at deep levels, where pressure and temperature are sufficient to make the gas from buried organic debris.

Most gas found in aquifers is biogenic. Rarely thermogenic gas can be found, so it is really important to know the back-ground levels so that one can be sure that the gas that has been detected represents an anomaly. The British Geological Survey is in the process of compiling that data for the UK.

This implies that all the bubbling streams, flaming faucets and so on that you may have seen in videos are likely to have nothing to do with hydraulic fracturing. The film Gasland (and Gasland II) deliberately mislead the public because it is known that its producer knew that the source of gas predated fracking in the area. Although many consider the film(s) fraudulent, and would consider it a shame if you and others were led by the nose by them, both films do contain some factually accurate information.

One extra word here, many houses in Canada have no source of water except their wells. A common method for reviving an old well where the water production rate has fallen off has been, for almost a century, a mini-fracking of the aquifer using propane gas. After such a treatment the well performance improves. The well cannot be used for a brief period, but there is no long term damage to the aquifer, only benefits of improved water flow. This lends an aspect of perspective to the discussion.

Contamination pathways

There are three theoretical contamination pathways:

A: Through damaged or incorrectly constructed casing.

B: Directly from the shale gas-bearing rock through the newly created fractures and pre-existing fractures or through the shale matrix.

C: Directly into or onto the surface environment and hence into surface aquifers.

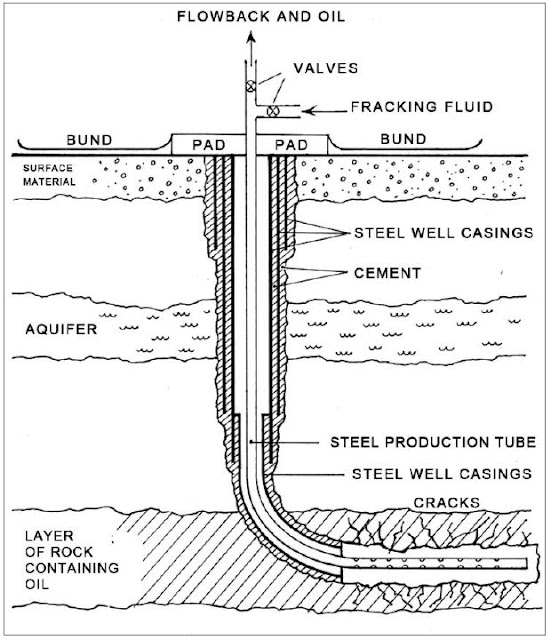

These pathways are shown in the figure below. In each case there is a theoretical possibility of contamination. The significance and possibility of each can be examined. Many depend upon open fractures, and we can monitor the creation of fractures by using micro-seismic monitoring.

Micro-seismic monitoring

The latest UK government hydraulic fracturing guidelines and the UK Onshore Operators Group guidelines for Onshore Shale Gas Well Guidelines both make microseismic monitoring compulsory in the UK. Such monitoring measures the size and position of fracture formation in the sub-surface. The presence of an event at a certain position during or after hydraulic fracturing indicates strongly that the hydraulic fracturing process has induced it. One cannot be 100% sure because there is a background of natural events whose rate can be determined by monitoring prior to fracking, but whose positions cannot be predicted.

Moreover, although we can be fairly sure that hydraulic fracturing has induced a fracture at a given position, it cannot be assumed that an open fracture has formed from the well to that position unless there is a progressive series of events between the well and the event. The reason for this is that micro-seismic events may occur due to fractures that form away from the borehole which result from stress changes in the rock that are caused by the hydraulic fracturing. However, the extent of those fractures is small and they are not connected to the rest of the fracture network and the well itself.

The ‘length’ of hydraulic fractures

In 2012 Davies and others carried out an independent study of artificial hydraulic fractures using a large set of data from six shale gas rock formations in the USA. They found that most events are within 100 m of the well, although some are up to 400 m from the well. This data does not show that fractures propagated up to 400 m from the well as implied by the study. Let us assume for the sake of precaution that these are patent fractures through their entire length. The reason for such fractures might be fracturing along occasional weaker, more brittle zones or previously existing fracture and shear zones.

The figure below shows the position of the well and that of the events. There is a small difference between upward propagating events and downward propagating events, in that the upward events tend to be further from the well on average, but the furthest events are about the same distance from the well both above and below the well.

The depth of shale gas rocks

By contrast, the depth of the top of shale gas resources which is given in the recent DECC report on the Bowland Shale in the UK is defined as 5000 ft. (1524 m). Consequently, there would be a thickness of at least 1100 m of rocks between the maximum extent of the fractures and surface aquifers or the surface itself. Is it enough?

In the UK, most of that rock cap is shale. Shales are incredibly good seals that stop the movement of fluids and are an essential part of any conventional hydrocarbon reservoir as the cap rock. We can carry out calculations to identify how long shale gas would take to travel through the remaining 1100 m of rock and penetrate an aquifer. The result is over 350,000 years and could be a hundred times higher than that.

Summary of leakage directly from the gas-bearing shale

So, the chance of us contaminating an aquifer or the surface from this pathway is negligible. It would require the presence of an already open fracture spanning the entire depth to the shale gas formation, and those do not form in plastic shales, as discussed in the posting on earthquakes.

Despite the long timescales, natural leakage by this path has probably been happening for millions of years, contributing to the natural back-ground levels of hydrocarbon gases in the atmosphere. This is a very slow process.

So where has the gas that has been videoed bubbling out of streams coming from then?

There are several sources, some natural and some not.

Most commonly the gas is biogenic and comes from shallow in the crust and is very local. Although it may be formed naturally in rocks around surface aquifers, but is more likely to be formed at very shallow levels where organic sediments laid down by the stream are decaying.

The gas can, however, be thermogenic. In this case the thermogenic gas comes from rocks that have been at great depth where the thermogenic gas was formed. However, the gas has not found its way to the surface, it is the rock itself that has been brought to the surface by erosion and uplift, and produces a small steady exhalation of gas from shallow depths.

Finally, it may be biogenic or thermogenic gas that has been disturbed by the drilling and which has leaked along the casing of the borehole before finding an easier pathway to the surface through permeable strata that may include potable aquifers. This scenario is considered below.

Intersecting an aquifer with a bore-hole

The borehole through which the drilling and fracking and flow-back fluids flow often passes through a surface aquifer, and sometimes that aquifer is used for potable water. It is essential that the borehole is drilled in a safe manner and that it remains safe. Many of the problems with gas leakage in Canada and some in the USA were associated with bore-hole problems.

It is important to know that before a well is drilled in the UK, its design and construction must be approved by the Health & Safety Executive (HSE).

How to drill a well

The figure below is taken from the report entitled “Fracking: A report on the risks and benefits associated with the proposed exploration for oil at Lower Stumble, Balcombe” by a working group of the Balcombe Parish Council. It is particularly clear.

Courtesy of Balcombe Parish Council

The drilling rig is set-up on a concrete pad surrounded by a large liquid-proof membrane called a bund, which is there to capture any spilt fluids, and to hold them until they are removed safely.

Drilling is a routine operation. A drilling bit is attached to a section of drill pipe which is rotated by the drilling rig. As the bit descends into the ground, additional sections of drill pipe are added to form a “drill string”. Drilling mud (a mixture of water and mud) is pumped down the drill string to cool and lubricate the bit, to bring the cuttings of rock to the surface and to act as a liquid plug for the well. The presence of the mud ensures that pressurised fluids in the rocks at depth do not come out of the well. The drilling mud is sieved to remove the drill cuttings, which are analysed, and can then be reused. The drilling mud is recycled at the end of drilling and can be used in other wells.

Once the drill bit has cut through the soil and loose surface material to a level above the aquifer, it is withdrawn and a steel casing (typically 60 cm diameter with a thickness of about 1.5 cm) is installed. Cement is then pumped out of the bottom of this casing, from where it travels upwards, filling any space between the outside of the casing and the surrounding ground. The ground that has been drilled up until this point is then protected from the contents of the borehole by a steel casing and a layer of cement.

When this has been completed drilling continues using a smaller drilling bit through the aquifer to a level below it. A smaller casing is then installed in the same manner as before. Any space outside the smaller casing and between the two casings up to ground level is filled with cement. Now the topmost part of the well is sealed from the borehole by two layers of steel casing and cement.

As the depth is increased further, the diameter of the bit and the casing are further reduced, and again the space outside the casing and between the casings up to ground level is filled with cement. The figure shows the well completed with three casings and a production tube. In environmentally sensitive areas it is becoming the norm to use four casings, which results in the aquifer being protected from the contents of the borehole by three layers of steel and cement.

In the case of the Balcombe drilling project, the well was planned to have at least two layers of steel casing and two layers of cement between the production tube and the aquifer.

This all seems very clinical and secure – can it go wrong? Well, yes and no!

Leakage of fluids into an aquifer

There is no evidence of leaks of drilling, fracking or flow-back fluids into the ground due to cement and casing failure. It is considered that the chances of such a failure are very small.

In the case of drilling fluids, the leak would not penetrate further than the natural invasion that happens when the well is drilled, and that is restricted to a few metres around the well bore.

In the case of fracking fluids, the high pressures used would ensure that a leak becomes obvious extremely quickly and lead to a cessation in fracking.

Failure during fracking that leads to a leak in the flow-back fluids might be more likely, but the period of flow-back is so short that a small amount of fluid would be leaked.

I have searched the literature for real evidence of fluids leaking through casing and found none. That, however, does not mean that it has not occurred and been unrecognised or the potential for a leak of these fluids is zero. In my view, the chances should be negligible if the well has been constructed to the guidelines of the UK Onshore Operators Group.

Indeed, writing in the New Scientist in 2012, Mike Stephenson, Head of Energy Science at the British Geological Survey, said “…there is no peer-reviewed evidence that frack fluid can leak into groundwater.”

Leakage of gas into an aquifer

It is true that tens of thousands of wells are drilled around the world each year and only a tiny fraction seem to have problems. That is what the drilling industry will tell you. But when detailed analysis is carried out, between 5 and 10% show leaks of gas around the bore-hole to some extent, although in many cases the leak is extremely small and a negligible fraction of the produced gas. The leaks come from between the cement and the rock, and the cement and the casing, through the cement itself, and rarely through breaks in the casing.

The gas is often biogenic, but sometimes thermogenic, and comes from the soil and rocks through which the borehole passes but which are not the target of the borehole. I have heard it said in the industry that these small leaks do not matter because they are not the result of hydraulic fracturing. However, that misses the point entirely. The fact is they are the result of drilling the borehole - perturbing the natural environment. Furthermore the leaks will increase as the well gets older. Cement decays, casing rusts and although regular and scheduled maintenance may be done, it never leaves the well in an ‘as-new’ condition. Regulations which address the long-term viability of wells should be put in-place.

It must be understood that although the burning of shale gas causes much less CO2 emission than coal, and is seen as an environmental advantage, if 10% of the produced gas (predominantly methane and ethane) enters the atmosphere directly (i.e., from leaks without being burned), its greater potential for green-house warming would completely cancel out any environmental advantage over coal. We must, therefore, be extremely pernickity over any gas leaks.

However, most leaks are relatively small and most leaking gas is gathered up and processed by the rig, but not all of it. Commentators on both sides will talk-up their point of view with the oil and gas companies claiming tried tested and safe methods, while others follow a scientific path so far, then lapse into unsubstantiated claims because there is much we do not know. So far the UK government has been particularly tardy at commissioning robust scientific studies to address some of the gaps in our knowledge.

The bottom line is that a significant number of wells leak no matter how carefully they are constructed, and we do not have the technology to stop them. It may not be necessary to develop new drilling technology providing the leaks are monitored and proved to be small. Maybe we need gas collection technology around the well-head. New regulation is one way of ensuring that this potential problem is not ignored. After all, methane is a very powerful green-house gas and all leaks are harmful to the atmosphere, wherever they occur.

Summary of leakage from the bore-hole

In summary, the contamination of an aquifer with drilling, fracking or flow-back fluids is extremely low. However, there is a chance of significantly contaminating an aquifer locally with hydrocarbon gases, especially if the well has been drilled, completed, or fracked in a reckless fashion. Guidelines are in place to ensure that this does not happen, but further regulations and enforcement are, in my view, necessary to ensure that contamination is reduced to insignificant levels, as well as to allay the fears of local communities.

Surface contamination

This pathway to pollution is probably the easiest to envisage, and is similar to spillage associated with any industrial process. The difference is that the spillage will likely occur in an unspoilt countryside area. We should be correspondingly careful.

Spillage may occur from faulty valves, tanks and pipes as well as from pools that hold fluids temporarily. In each case, the spillage needs to be contained and mopped up, with no leakage into the ground, surface waters or aquifers.

Although industrial spillages are rare, they are inevitable and so we should be prepared for occasional spillages in the development of the shale gas industry. Regulations are already in place, and they should be matched by emergency protocols and clean-up teams on stand-by, just as we have for oil spills at sea.

Summary of surface contamination

I consider this route to be the most likely for causing long-term environmental damage. Any damage might be amplified a hundred-fold by being inattentive, unprepared or inactive.

None of the fluids are as highly toxic as has been advertised by their detractors, nor as harmless as made out by their supporters. All of them can be remediated if action is taken swiftly, and none of them should be allowed to continue in the natural environment if a spillage occurs.

While the chances are small, one would expect there to be spillages in a mature shale gas industry. Consequently, regulations, procedures and emergency spillage teams should be developed.

In overall summary, there is a significant risk of occasional surface and aquifer contamination from the exploration, stimulation and production of shale gas. The most likely pathway is from surface operations. Regulations, protocols and spillage response teams should be developed to counteract any incidents. There is an unresolved issue whether gas leakage into aquifers as a result of incomplete sealing will be a significant problem. Urgent research into this aspect is required.

No comments:

Post a Comment